WATERJET CUTTING SERVICES

Waterjet cutting has innovated the way in which the oil and gas industry operates, opening new possibilities and improving the performance characteristics of conventional operations. This article will explore the applications of water jet cutting for oil and gas industry, along with the benefits of the same. This can be use to cut crude oil tanks, oil pipes and creating round holes in tanks and pipes.

Usefulness:

Internal Cutting: Waterjet cutting can cut the insides of pipes and other parts, removing flash and sludge. There are not many other cutting processes that can accomplish this.

No Heat-Affected Zones: Alternative cutting processes heat the edges of the material while cutting, leading to the formation of heat-affected zones. Heat-affected zones alter the physical and chemical properties of the material. However, since waterjet is a cold-cutting process, there are no heat-affected zones to worry about.

Safety: Due to the nature of the oil and gas industry, alternative cutting processes come with the risk of fire hazards and explosions. Due to waterjet being a cold-cutting process, there are no such risks.

Cost Effective: By offering high cutting speed and precision, waterjet turns out to be a more cost-effective option as compared to its alternative. Additionally, a single machine can support multiple cutting heads and can cut multiple sheets of material simultaneously, increasing production rate exponentially.

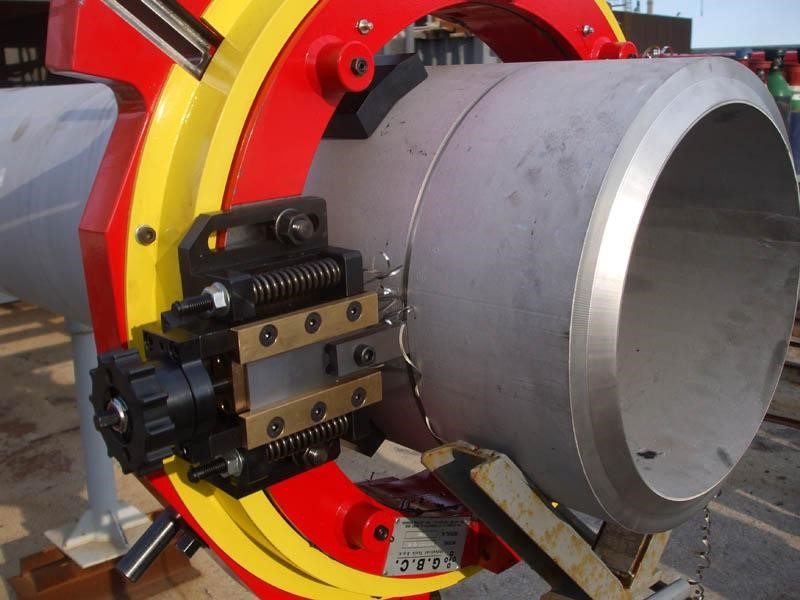

COLD CUTTING SERVICES

As part of the comprehensive conductor installation service, the conductor is cold cut once it has been driven into the seabed. in addition, internal and external bevels are cut to suit client specifications. This leaves the client with a fully installed conductor that is ready for wellhead installation. Lightweight, slimline, cold-cutting tools are used so that work can be carried out on platforms that have live producing wells without loss of production.

The air-driven cutting machines are suitable for use in hazardous environments. Their lightweight sectional design means the machines are simple to install around casing, and they also are easily adjustable for cutting at a range of part-off heights. In addition, the cold-cutting operations are classified as cold work, so no hot-work permit is required.

Precision machine-finish cutting of tubing, casing, conductors and piles ranging from 5” to 36” in outer diameter. Cold cutting services are offered both as standalone service or as part of an integrated conductor installation package.

Cold cutting system benefits:

- Lightweight modular design allows easy installation and quick adjustment

- Increases safety and improves operational efficiency

- Rugged field-proven design

- Simultaneous cutting and beveling

- Can be easily moved around for effective jobs.

- No flames or sparks that could ignite hydrocarbons means no risk of fire and explosion.

- Casings and Conductor Pipes are easily cut and beveled ready for wellhead installation

- Lightweight and Flexibility – Easily installed around casings and conductor pipes.

- Equipment can easily be adjusted to fit most wellhead types

- Cutting of casings tubing

- Large diameter conductor pipes ranging from 20” to 42” can be cut

- Cold Cutting on Live Producing Wells without shut-down and loss of production

Our cold cutting system produces a lathe-type bevelled finish on casing ends without altering metallurgical properties, and is widely used in decommissioning, wellhead Installation and in Tieback Operations on Oil & Gas Production Platforms, Petrochemical industries. Contact us for your cold cutting operations.

Subsea Cutting (Diamond Wire Saw)

With subsea diamond wire saw, subsea and underwater cuttings is made easy. Our Diamond wire saw cutting machine is specifically designed for subsea pipe cutting of varying materials and thicknesses, can cut concrete, metals, combination of metal and concrete or any material.

This machine can cut horizontal or vertical pipes or structures. Running on Hydraulic Power, the saws are controlled remotely with dedicated HPU controls, top side control panels or by ROV control operable via zero leak hot stabs.

With this subsea diamond wire saw, cutting underwater is made easy. This equipment is applicable in Oil and Gas, Construction, Marine and any other subsea projects.

Nut splitters

The range of Nut Splitters are the ideal tool for removing corroded and seized nuts. The design incorporates a single acting spring return, and eliminates the need for grinding or flame cutting and associated safety issues. The heavy-duty blades can be easily removed and are triple edged giving extra longevity. We have different sizes and with request we can produce the right size for the job.

Pneumatic Hacksaw

Pneumatic Hacksaw is use for cutting pipe, tanks, structural steel, profiles and more. Pneumatic motor with variable speeds from 100 to 350 strokes per minute can cut pipe up to 30″ OD in one pass.

We also offer both electric, thermal and hydraulic services for industrial use.